HCV Valve Design

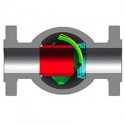

Defining feature is the cartridge design, whereby all the valve’s internal parts (core, hemi, seat, stem, bushing) are affixed to the bonnet and may be removed by simply unbolting the bonnet fasteners and lifting the cartridge from the valve body. No special tools are required. Rapid replacement results in incredible maintenance cost savings and minimizes downtime.

Features & Benefits

The HCV Valve is designed with key features that deliver benefits for your application. Some of the key features include the following:

- Mechanical Seal

- Stationary Core

- Unique Cartridge Design

- Quarter-turn Operation

FEATURE: MECHANICAL SEAL

Tapered hemispherical closure member (Hemi) rotates around a stationary core. The Hemi wedges into a seat applying an independent positive load as a result of the taper for a reliable bubble-tight shutoff.

Tapered hemispherical closure member (Hemi) rotates around a stationary core. The Hemi wedges into a seat applying an independent positive load as a result of the taper for a reliable bubble-tight shutoff.

BENEFITS:

- Hemispherical Closure Member Applies Independent Load to Seat

- Valve will seal at both low and high pressures

- Resilient Seals or Metal-to-Metal Seats available

- Zero-leakage (bubble-tight shutoff) resilient seat, Bi-directional sealing

- ISO 5208 Rate A (Zero Leakage) or Rate B shutoff for metal-to-metal seat

- Low hydrodynamic torque in high flow

- Segmented sphere option allows for throttling applications

- Improved closing reliability in ESD application

- Suitable for thermal cyclic applications

FEATURE: STATIONARY CORE

The stationary core within the HCV Valve protects the seals and seating surfaces from media flow, providing greatly increased service life and reliability.

The stationary core within the HCV Valve protects the seals and seating surfaces from media flow, providing greatly increased service life and reliability.

BENEFITS:

- Flow is not directed at seats during operation

- Service fluid (and entrained particulates) is directed away from sealing surface minimizing erosion of seats

- Flow is not directed at valve body wall – low erosion of pressure containing components

- Low turbulence and reduced erosion of valve internals

- Low hydrodynamic torque

- High flow coefficient

- Valve is through conduit – Can pass pigs

FEATURE: UNIQUE CARTRIDGE DESIGN:

All trim components are housed in a single pre-tested cartridge which can be easily replaced without special tools or pulling the valves from the line. Rapid replacement reduces maintenance costs.

All trim components are housed in a single pre-tested cartridge which can be easily replaced without special tools or pulling the valves from the line. Rapid replacement reduces maintenance costs.

BENEFITS:

- Easily Removable/Replaceable Cartridge

- Ability to easily and quickly inspect valve

- Easily capable of revising trims for throttling

- Fewer parts to stock

- Minimal downtime for valve repair

- No special tools required for service

- Easily capable of changing from resilient to metal seats

- Ability to install a temporary strainer for startup purposes

- Ability to install a temporary trim for welding valves in line

- Confidence in making a reliable repair with pre-tested cartridge

- Significant Reduction in Downtime – Top Entry

- Weld end valves do not have to be removed and/or reinstalled

FEATURE: QUARTER-TURN OPERATION

The quarter-turn (90°) operation is consistent with industry standards and helps in delivering an overall lower total cost of operation.

BENEFITS:

- Easy to automate

- Lower emissions than rising stem designs

- Easy packing adjustment to stop external leaks

- Low profile for use in skids and offshore applications

- Utilizes existing ball valve actuation and sizing principles

- Faster more reliable closure for ESD applications

Tapered hemispherical closure member (Hemi) rotates around a stationary core. The Hemi wedges into a seat applying an independent positive load as a result of the taper for a reliable bubble-tight shutoff.

Innovative Cartridge Design

The HCV Valve’s defining feature is its cartridge design, whereby all the valve’s internal parts (core, hemi, seat, stem, bushing) are affixed to the bonnet and may be removed by simply unbolting the bonnet fasteners and lifting the cartridge from the valve body. No special tools are required. Rapid replacement results in incredible maintenance cost savings and minimizes downtime.

Revolutionary Cartridge Design:

- Top Entry

- Ease of repair

- Reduced downtime

- Cartridge Interchangeability

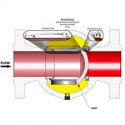

Mechanically Seated:

The HCV Valve’s innovative mechanically sealing principal, with the increased offset (shown in yellow) in the closed position, applies a positive force into the seat to provide reliable, bubble-tight sealing in low or high pressure applications.

- Hemiwedge® mechanical wedge

- Bubble tight sealing / Bi-directional

- Sealing at low or high pressure

- Reduced load during operation

Unique Stationary Core:

The seats in the HCV Valve design are never exposed to direct impingement of product flow greatly reducing the potential for damage and or erosion.

The seats in the HCV Valve design are never exposed to direct impingement of product flow greatly reducing the potential for damage and or erosion.

- Seats protected from product flowhemiball-compare.jpg

- Reduced turbulence

- Eliminates pressure cuts on seats

- Comparative flow to ball valves

Double Block and Bleed

Chromatic can provide a valve that meets the pipeline description of Double Block and Bleed and meet testing requirements established by API 6D for both Double Block and Bleed and Double Isolation Block. By converting the stationary core into an extended upstream seat, we are able to provide two independent seats/seals that can provide a verifiable bubble-tight/provable seal repeatedly.

Chromatic can provide a valve that meets the pipeline description of Double Block and Bleed and meet testing requirements established by API 6D for both Double Block and Bleed and Double Isolation Block. By converting the stationary core into an extended upstream seat, we are able to provide two independent seats/seals that can provide a verifiable bubble-tight/provable seal repeatedly.

This design configuration was developed for a customer in requesting a Double Block and Bleed valve for the specialty gas industry. Their final testing requirements included subjecting the valve to API 6D DBB parameters, after 200 cycles, with Helium. The valve held bubble-tight.

Specifications

HCV Valves are available in a variety of sizes, pressure classes, materials, and trims. The basic design is easily scalable. Additional sizes, pressures classes and features are continually under development to meet industry needs.

Materials: Carbon steel (A216 GradeWCC), impact-tested carbon steel (A352 Grade LCC), stainless steel (A351 Grade CF8M) are the most typical alloys offered, but other alloys are available for body/bonnet or internals depending on service conditions. Trim materials are available in a variety of alloys to meet NACE requirements and other corrosive environments.

Seats/Seals: The selection of seat/seal material is dependent on the service fluid and temperature, and includes various common elastomers such as Viton® and HSN, or synthetic materials such as Teflon®, Tefzel®, PEEK, or Metal-to-Metal seating for higher temperature or severe services. We also have a DOUBLE BLOCK AND BLEED option that provides the ability to positively load (irrespective of pressures) both the upstream seat and downstream seat and positively prove the sealing capability of the valve in either full (thru-conduit / pigable) or reduced ports.